Ultraprecision Alignment in PIC R&D Workflows

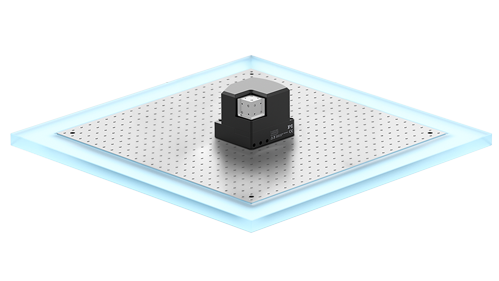

6-Axis Piezo System for Fast Alignment

Photonic integrated circuit (PIC) innovation requires ever-tighter alignment precision as device architectures grow more complex and coupling tolerances shrink. In R&D environments, measurement fidelity and engineering velocity hinge on fast, deterministic multi-axis alignment—capabilities that conventional mechanical stages simply cannot sustain at the nanoscale. PI’s NanoCube® overcomes these limitations with true 6DoF piezo motion, nanometer precision, and exceptional dynamics, delivering the performance required for next-generation PIC testing and probing. Engineered with a compact parallel-kinematic design, flexure guidance, and proven PICMA® actuator technology, NanoCube® sets a new standard for ultraprecision alignment in benchtop experiments, advanced characterization workflows, and automated photonics probing systems.

Key Technical Highlights

- Ultracompact 6 axis platform (6DoF): small enough to fit in the palm of a hand, ideal for benchtop experiments and space constrained R&D workstations

- Precision motion with nanometer resolution: 500 µm linear travel range (X, Y, Z) and 3° rotation (θX, θY, θZ)

- Exceptional dynamics enabled by parallel kinematic flexure guidance and proven PICMA® piezo actuator technology ensuring reliability for complex, sensitive PIC samples

- User programmable virtual pivot point for flexible multi axis alignment—even in demanding PIC architectures

>> P-616.65S NanoCube®

Smart Firmware for Faster Alignment

- Integrated with PI’s E-713 controller enabling precise, synchronized motion control

- Built-in high-speed routines with automated first-light detection, gradient search, and multi-axis optimization

- Runs entirely in firmware eliminating the need for external scripts or PC‑side processing

- Shorter alignment cycles for improved throughput in R&D and production

>> E-713 Motion Controller

Do you have questions about our solutions? Our specialists are happy to help you!

Kontakt aufnehmen!